About us

We are the epitome of Net Zero Steel

AGSI is the first in The World carbon Neutral Steel Plant and Net Zero Steel Manufacturing Facility based in Abu Dhabi, UAE, certified by a leading global third-party assurance. We are championing and accelerating the UAE’s path to the Net Zero by 2050 and pioneering the most sustainable steel manufacturing across The Middle East.

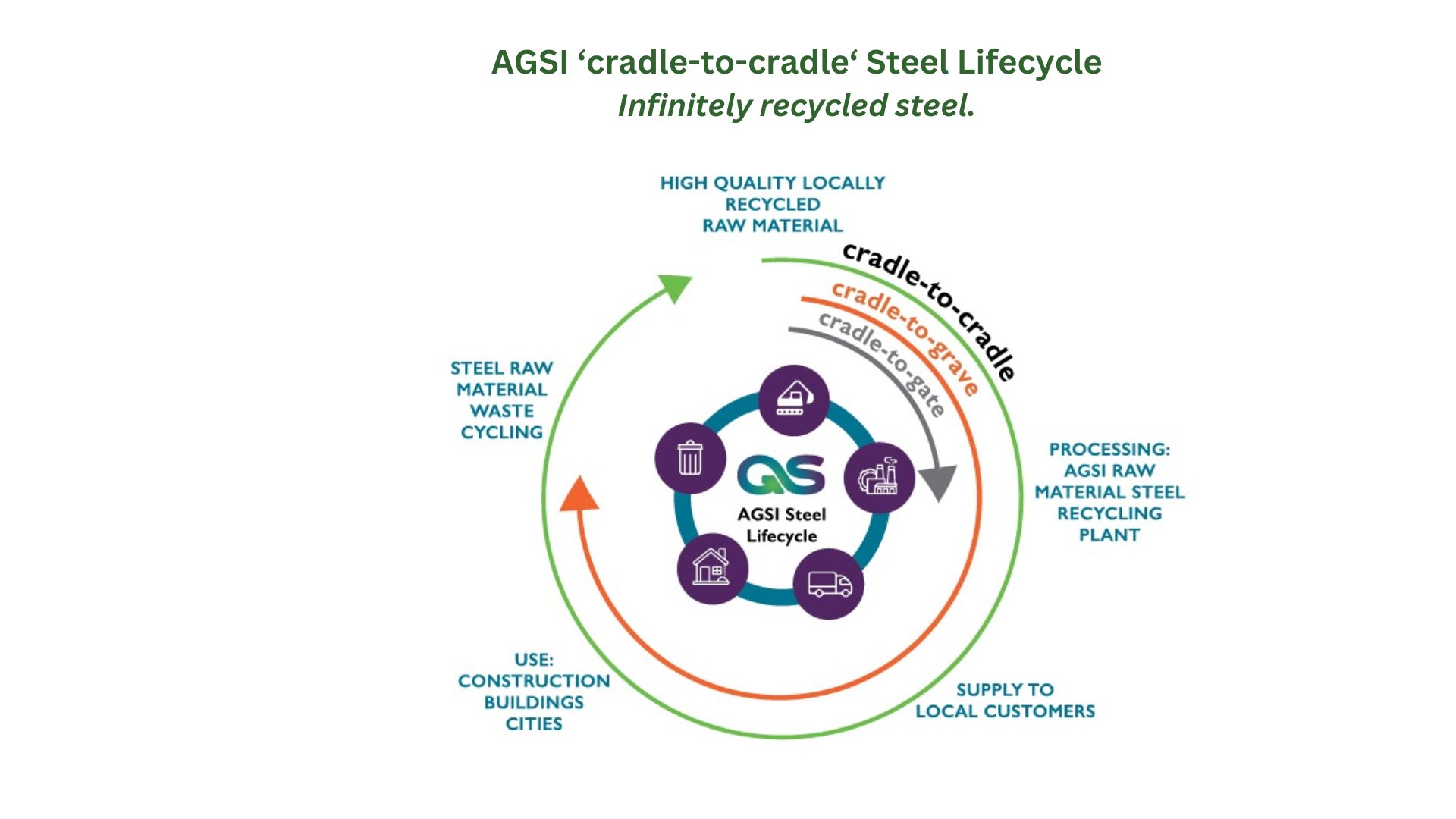

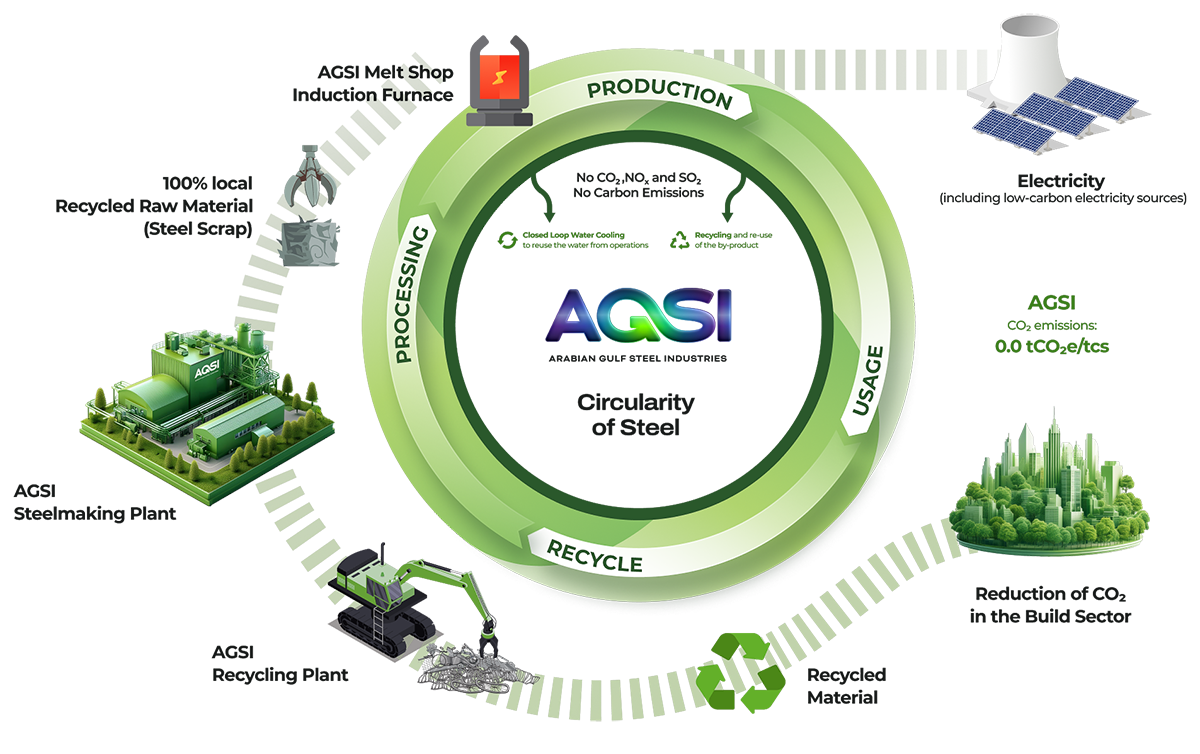

We produce steel from 100% locally sourced recycled steel raw material for domestic building and infrastructure projects. This positions us as the Epitome of Circular Economy through continuously recycling the UAE’s steel raw material and producing new steel in an emission-free process for the local built environment, while at the same time recycling and reusing all our waste from the operations. This continuous process creates an endless Circularity of Steel.

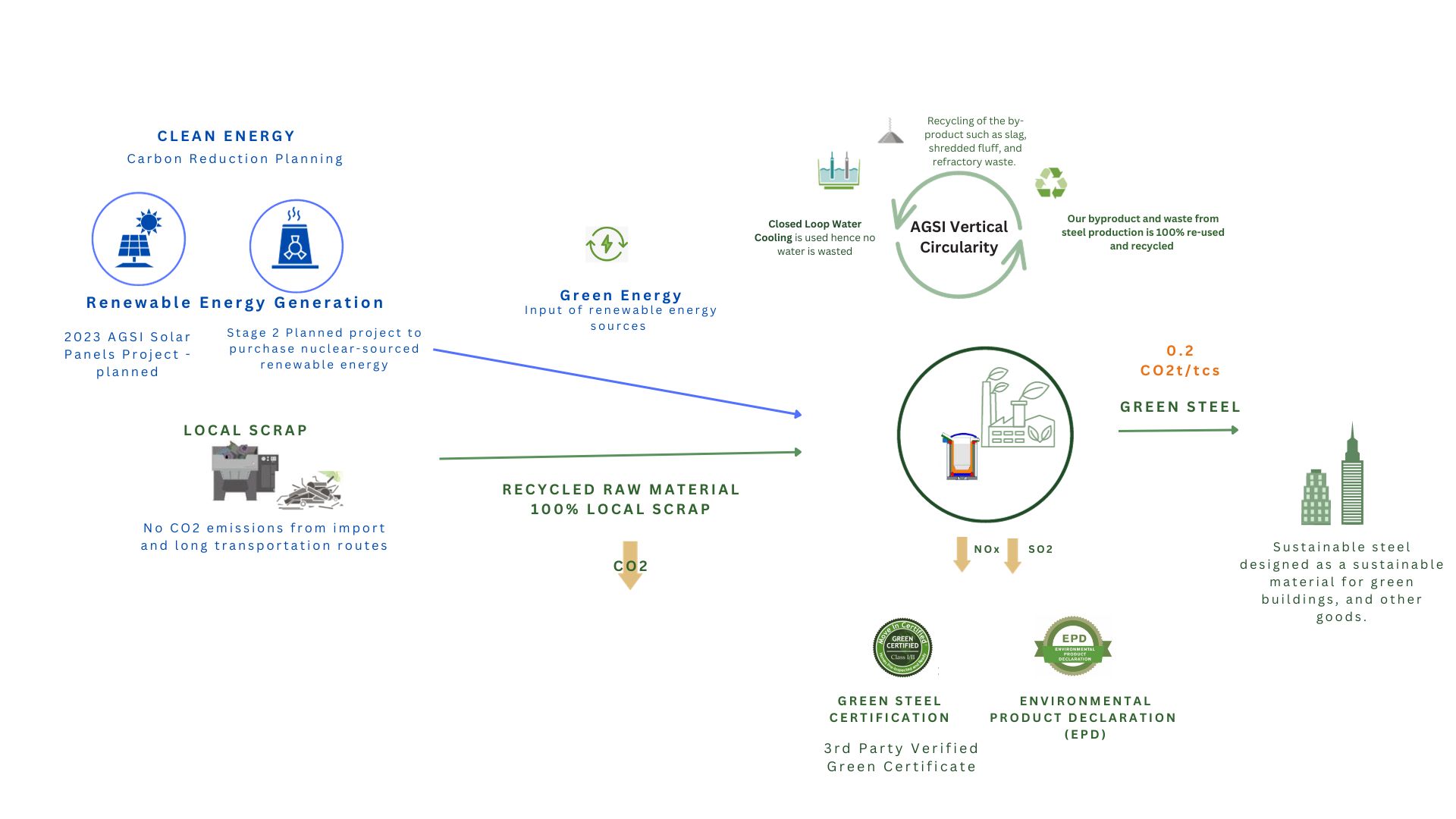

Our locally produced recycled steel is integral to suppressing carbon emissions and resource consumption. The Net Zero Steel products reduce carbon emissions by 79%-95% compared to an industry average for conventional steel-making. This represents a significant opportunity to decarbonize the built environment.

Additionally, our 100% domestic scrap-based steel production is contributing to significant saving of CO2 and lowering the country’s carbon footprint and helps decarbonize the UAE’s steel industry to a very low base.

MISSION

We are on the mission to revolutionize the steel industry by bringing greener and more sustainable solutions to the world.

VISION

Our vision is to be the leading green steel producer providing sustainable products that contribute to the green economy, setting the benchmark for sustainability and excellence in the industry. We envision creating a legacy of excellence, innovation, and environmental stewardship in the steel industry, inspiring others to follow suit.

Our products are certified with a Green Steel Certification issued by a third-party verification auditor. We produce the highest quality of steel that is sustainable, yet durable with qualities of traditional steel.

Values

Sustainability

We prioritize sustainable practices in every aspect of our operations, minimizing our car¬bon footprint to net-zero and conserving resources to protect the planet.

Innovation

We embrace continuous improvement and innovative solutions, driving progress and excellence in the steel industry for generations to come.

Employee Empowerment

We empower our employees to be champions of sustainability and innovation, fostering a culture of collaboration and growth.

Customer-Centricity

Our customers needs are at the heart of everything we do. We strive to exceed their expectations by delivering exceptional quality and service while contributing to their decarbonization goals.

Integrity

We conduct business with the highest level of integrity, honesty, and transparency, building trust with our customers, partners, and employees.

The Road to Sustainable Steel

Driving Innovation and Investments to decarbonize

By utilizing steel raw material bought locally powered by renewable energy production, we can significantly decarbonize the steel industry. AGSI aims to substantially expand its capacity and operations and to create net-zero value chain with our partners and customers to secure its position as the driving agent in the green steel production worldwide.

We invested heavily in modernization of our technology and expansion of operations in our steel plants. Our innovation will further reduce energy consumption and completely optimize the operations, leading to net-zero emissions. Our expansion projects are presently on the way to further innovate our operations leading to increased production capacity with a goal to supply more sustainable steel for building green and sustainable buildings and cities.

Additionally, we are investing in further sources of renewable energy to run our operations through solar panels and nuclear energy.

Net Zero is not only central to our business strategy - it is our strategy.

Swift towards a greener future

The world needs green steel

As urban areas and populations around the world continue to grow, so will the demand for steel. It is the most used material in the world, a vital structural component of buildings, cars, infrastructure, and consumers durables. Global steel demand is expected to grow by 40% in 2050, whilst simultaneously greenhouse gas emissions should decrease by 95%. (Source: International Energy Agency, IEA). Only by substantially reducing emissions within this decade, we will be on the path to meeting the 2050 Net Zero targets.

Why do we do this?

The world needs steel. It’s strong, durable, and infinitely recyclable – it doesn’t lose its inherent properties or qualities during its recycling process, making it continuously reusable.

However, traditional steelmaking has a heavy environmental impact and carbon footprint. Steel industry accounts for 7% of the world’s CO2 emissions.

But this can – and must – change.

By incorporating recycled steel into production and electricity powered production, AGSI can help achieve a circular economy and reduce the environmental impact of the steel industry, while supplying the highest quality of steel to our clients. Furthermore, with our heavy investments into upgradation and automation of our operations, our products will have virtually zero carbon footprint.

AGSI New Era of Steelmaking

We are proud of the Circularity of our operations, whereby all materials that we use, by-products or waste are repurposed - either re-used or recycled indefinitely across our processes, from processing, production, to operations. This makes our steel ‘circular’ and reduces the impact on environment to minimal. This means that our raw material and products are ‘in the economic loop’ that reduces the carbon footprint.

Nothing goes to waste

We further lower carbon footprint in our operations through the vertical circularity along our value chain through reuse and recycle of any byproduct or waste. For example, we re-use the wasted (or by-product) from scrap processing, such as slag, shredded fluff, refractory waste, for various industrial applications or mill scale is 100% reused as scrap again to produce steel. In addition, we reuse the water in the ‘closed loop water cooling system’ so no water is wasted.